Coal Briquetting Machine

Feed Size : Less than 5mm

Capacity : 2-30t/h

Application Fields : suppress various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum.

Introduction : Coal Briquetting Machine, also called coal powder briquette machine, belongs to one of briquette machines. The main function of coal briquette machine is to press the spread coal powder and coal dust into briquettes, and add a certain amount of adhesive in the necessary time to improve the burning heat value of briquettes.

Coal Briquetting Machine, also called coal powder briquette machine, belongs to one of briquette machines. The main function of coal briquette machine is to press the spread coal powder and coal dust into briquettes, and add a certain amount of adhesive in the necessary time to improve the burning heat value of briquettes. This machine not only solves the problems that coal powder is easy damp and not convenient to transport and use, and also makes the coal powder burn more sufficiently, reduce dust and improve resource utilization rate. Coal powder briquette machine has the economic and social benefits.

The Features of Coal Briquetting Machine

1. It is mainly used for pressing briquette generated from coal washing plant or power plant into lumps or balls. The coal briquette can be directly put into the furnace for combustion or smelting, so as to increase the added value and achieve the reuse of resources.

2. Coal briquetting machine is a kind of equipment used for making coal briquettes or coal powder, which has extremely extensive applications. Its purpose is to reduce dust, control the bulk density, return to use and improve transport properties. It has started in the world, which not only can increase the efficiency of enterprises, but also reduce the waste of resources.

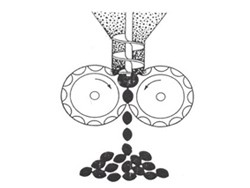

Structure of Coal Briquetting MachineCoal Briquette Machine or Coal Briquetting Machine consists of three parts: feeding part, driving part and molding part

1. Feeding part, it mainly achieves quantitative feeding so as to ensure the materials get into the roll uniformly.

2. Driving part, the main driving system of driving part includes: motor/triangle strips/reducer box/exposed gear/roll.

3. Molding part, it mainly refers to the host position and its core part is the roll.

Dongfang coal briquetting machines can be used to suppress various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum, gangue, sludge, kaolin, active carbon, coke breeze and so on. Coal briquetting machines and coal briquette machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries. The molding materials made by the coal ash briquette machines and coal briquetting plant are energy conservation and environment protection and easy to carry. Coal briquette press machine also improves the utilization rate of waste, which has significant economic benefits and social benefits

Main technical parameters of Coal Briquetting Machine

|

DF-290 |

DF-360 |

DF-500 |

DF-650 |

DF-750 |

DF-850 |

remark |

|

|

Capacity(t/h) |

0.5-1.5 |

2-3 |

5-7 |

10-12 |

18-20 |

25-30 |

|

|

Roller width(mm) |

250 |

280 |

300 |

336 |

400 |

500 |

(65Mn) |

|

Roller diameter(mm) |

290 |

360 |

500 |

650 |

750 |

850 |

|

|

power |

5.5kw |

7.5kw |

18.5kw |

30kw |

45kw |

75kw |

|

|

Spindle speed |

18r/min |

15 r/min |

13 r/min |

13 r/min |

13 r/min |

10 r/min |

|

|

reducer |

ZQ290 |

ZQ360 |

ZQ500 |

ZQ650 |

ZQ750 |

ZQ850 |

Standard Configuration |

|

Pressure form |

Constant pressure |

Either is ok |

|||||

|

Shaft seat rod |

Hydraulic |

||||||

|

Roller material |

65Mn |

65Mn |

65Mn |

65Mn |

65Mn |

65Mn |

Either is ok |

|

|

|

9cr2mn |

9cr2mn |

9cr2mn |

9cr2mn |

||

|

Alloy steel |

|||||||

|

Spindle(mm) |

Ø95 |

Ø110 |

Ø135 |

Ø165 |

Ø165 |

Ø180 |

|

|

45#steel |

45#steel |

Forge |

Forge |

Forge |

forge |

||

|

Ball size |

As clients requirement |

Usually 30-60mm |

|||||