Coal briquette ball pressure machine

Feed Size : HDXM-290

Capacity : 2.5t/h

Application Fields :

Introduction : Coal briquette ball pressure machine,Ball Press machine,ball pressing machine are the best known products.The products have got the international quality certification of ISO9001:2000 and the European CE certification

Coal briquette ball pressure machine can be used to suppress the pulverized coal, iron, coal, aluminum, iron, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sewage sludge, kaolin, activated carbon, coke powder and other powder, powder, waste, waste residue, widely used in power plants, metallurgy, refractory, chemical, energy, transportation, heating and other industries, after molding by ball press machine, the material features energy saving and environmental protection, convenient transportation, improve the utilization rate of waste, have good economic benefit and social benefit.

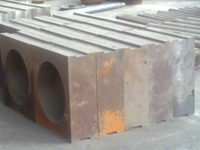

Type coal pressure ball machine structure and composition

1, the feeding part,is used to feed material so that the material can feed to rolloer evenly ,it is drived by Spiral comprises electromagnetic motor . the material through a belt wheel, a worm speed reducer to rotate, the pressed into the feed inlet. As a result of electromagnetic speed regulating motor constant torque characteristic, when a screw feeder pressure feeding quantity and host machine needed materials when equal amounts, can maintain a constant feed pressure so to keep pellet quality. If the feeding quantity is too large, then feeding device of electrical overload; the feeding quantity is too small then not into a ball. Therefore, the skilled operation technology is the key factor to guarantee the normal work of ball press.

The transmission part, main transmission system is: Motor - triangle belt - reducer - Open Gear - roll. Host machine powered by electromagnetic, from a belt wheel, cylindrical gear reducer, through the rod coupling pin to drive shaft. The driving shaft and the driven shaft through open gear ensures synchronous operation. Passive bearing seat is provided with a hydraulic device. Hydraulic protection device is composed of a hydraulic pump high pressure oil into the hydraulic cylinder, the piston to generate axial displacement. Piston rod connected to the front head on the bearing seat to meet the production requirements of pressure.

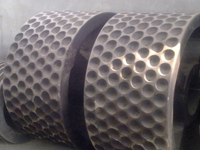

3. Forming part, mainly refers to the part of the host machine, its core part is roller. When the two roller feeded too much or enter the metal block, the piston rod of a hydraulic cylinder pressure overload, hydraulic pump will stop, the accumulator on pressure buffer, overflow valve opening oil return, piston rod shift of the press roll gap is increased so that the hard objects can pass through roller, pressure system returns to normal, thus can protect the roller without damage. The machine can adjust press according to press density , features flexibility.

Main technical parameters of Coal briquette ball pressure machine:

|

|

HDXM-290 |

HDXM-360 |

HDXM-500 |

HDXM-650 |

HDXM-750 |

HDXM-850 |

HDXM-1000 |

remark | ||

|

capacity |

Hour |

2.5t/h |

4.5t/h |

11t/h |

18t/h |

25t/h |

35t/h |

����45t/h |

| |

|

annual |

10,000t |

18,000t |

30,000t |

50,000t |

70,000t |

100,000t |

140,000t |

| ||

|

Roller width |

250mm |

280mm |

300mm |

336mm |

400mm |

500mm |

650mm |

(65Mn) | ||

|

Roller diameter |

290mm |

360mm |

500mm |

650mm |

750mm |

850mm |

1250mm |

| ||

|

power |

3.5kw |

11-5kw |

18.5-22kw |

20-30kw |

45kw |

75kw |

130kw |

material | ||

|

Spindle speed |

18r/min |

15 r/min |

13 r/min |

13 r/min���� |

13 r/min |

10 r/min�� |

10 r/min |

| ||

|

reducer |

ZQ290 |

ZQ360 |

ZQ500 |

ZQ650 |

ZQ750 |

ZQ850 |

ZQ1250 |

Stand Configuration | ||

|

ZQ360 |

ZQ400 |

ZQ650 |

ZQ750 |

|

|

|

Strengthen configuration | |||

|

Pressure form |

Constant pressure |

Either is ok | ||||||||

|

Shaft seat rod |

Hydraulic | |||||||||

|

hydraulic constant pressure exchange | ||||||||||

|

Roller material |

65Mn |

65Mn |

65Mn |

65Mn |

65Mn |

65Mn |

65Mn |

cast |

Either is ok | |

|

|

|

9cr2mn |

9cr2mn |

9cr2mn |

9cr2mn |

9cr2mn |

forge | |||

|

Alloy steel |

Die-casting | |||||||||

|

Structure form |

Dual roll single pressure |

Eigher is ok | ||||||||

|

Four roll double pressure | ||||||||||

|

Spindle bearing |

319*4 |

319*4 |

2097724*4 |

2097732*4 |

2097732*4 |

2097734*4 |

2097744*4 | |||

|

spindle |

��95mm |

��110mm |

��135mm |

��165mm |

��165mm |

��180mm |

��225mm |

| ||

|

45# steel |

45#steel |

Forge |

Forge |

Forge |

forge |

forge |

| |||

|

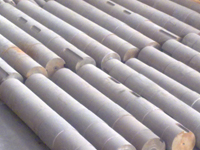

Ball size |

As clients requirement |

Usually 30-60mm | ||||||||